History of Laser Technology

Laser technology started with Albert Einstein in the early 1900s. The technology further evolved in 1960 when the very first laser was built at Hughes Research Laboratories. Follow the timeline below to see the evolution of laser technology.

Growth of Laser Materials Processing

1960s

The first CO2 laser, developed in 1964, had a power output of only one milliwatt. By 1967, CO2 lasers with power exceeding 1,000 watts were possible. The first commercial application of Laser Materials Processing was in May of 1967 when Peter Houldcroft of TWI (The Welding Institute) in Cambridge, England used an oxygen-assisted CO2 laser beam to cut through a sheet of steel 1 mm thick.

1970s

Continued refinements of CO2 lasers along with developments of new types of lasers ushered in the first “Laser Machining” applications. The first 2-axis laser system was developed in 1975 by Laser-Work A.G. The earliest applications were driven by automobile and aircraft manufacturers who were discovering the value of lasers for metal cutting and welding.

1980s

The introduction of small, inexpensive lasers such as the Carbon Dioxide Slab Laser, ushered in a new era of “Laser Materials Processing”. Applications expanded from metal cutting and welding, to processing organic materials such as plastic, rubber and foam.

1-Touch Laser Photo™

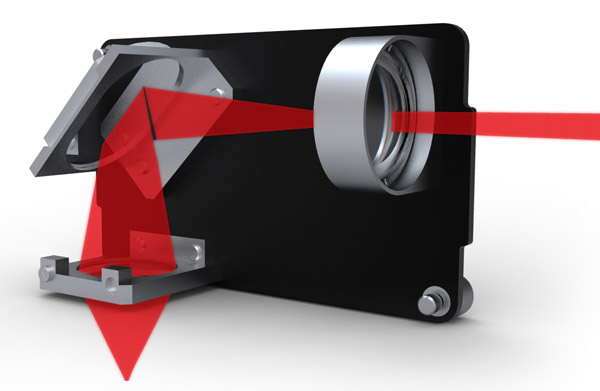

1-Touch Laser Photo™ HPDFO™

HPDFO™ Laser Interface+™

Laser Interface+™ Multiwave

Multiwave SuperSpeed™

SuperSpeed™ Ægte Class4 med gennemløb

Ægte Class4 med gennemløb Rapid Reconfiguration™

Rapid Reconfiguration™