Laser Material Processing

Laser Material Processing uses laser energy to modify the shape or appearance of a material. This method of material modification provides a number of advantages such as the ability to quickly change designs, produce products without the need for retooling, and improve the quality of finished products. Another advantage of laser material processing is compatibility with a multitude of materials. Compatible materials range from non-metals such as ceramics, composites, plastics/polymers and adhesives to metals, including aluminum, iron, stainless steel, and titanium.

Laser Energy - Material Interaction

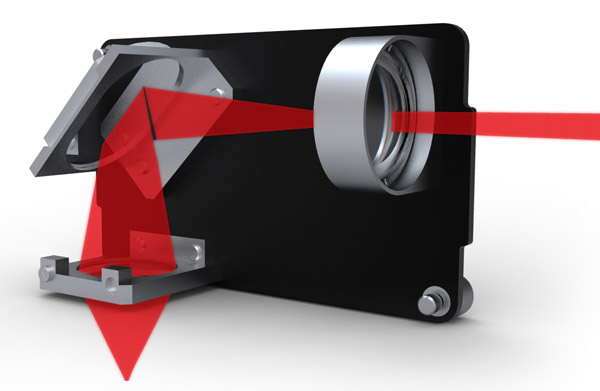

The effects produced by laser energy interacting with a material strongly depend upon the wavelength and power level of the laser and the absorption characteristics and chemical composition of the material.

Common wavelengths for laser material processing are 10.6 and 9.3 micron lasers and 1.06 micron produced by fiber lasers. A range of power levels is available for each laser type to optimize the laser energy-material interaction. However, the absorption characteristics and chemical composition of the material and the desired results greatly influence the selection of the laser type and power level.

The effects of the laser energy-material interaction are material ablation and/or material modification.

Material Ablation

This physical process removes material. Material is removed completely from the top to the bottom surface or partially from the top of the material down to a specified depth. Material ablation is used for laser cutting, engraving and drilling.

Surface Material Modification

This physical process alters the properties and/or appearance of a material. Material modification is used for marking on the surface of a material by changing the appearance or properties of the material.

The terms cutting, engraving, and marking are commonly referred to as laser processes. Depending upon material compatibility, a single laser process or multiple processes in combination can be applied to a material.

1-Touch Laser Photo™

1-Touch Laser Photo™ HPDFO™

HPDFO™ Laser Interface+™

Laser Interface+™ Multiwave

Multiwave SuperSpeed™

SuperSpeed™ Ægte Class4 med gennemløb

Ægte Class4 med gennemløb Rapid Reconfiguration™

Rapid Reconfiguration™